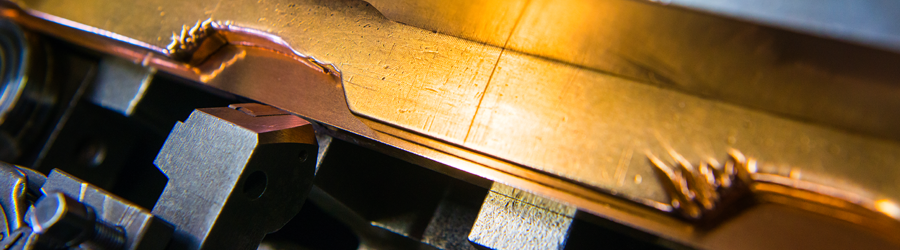

All metal-qualities are also available with a ceramic or tungsten carbid coating on the top of the blade / bevel. A longer life-time and a lower friction coefficient of the blade are just two advantages of this improved technology.

Please take further technical facts from our datasheet at the end of the page.

Doctor Blades with Tungsten Carbid

Material No.:

PW 100

Alloy No.:

2.4375 (Monel)

Description:

Ni Cu 30 AL

Hardness:

HRC: 26 – 32

HV: 270 – 320

Description:

cold rolled and hardened

Tensile strength:

850 – 1050 N/mm²

Surface:

bright

Substrate:

Monel

Lay:

Tungsten Carbid

Hardness Tungsten Carbid:

approx. 1200 HV

Colour Tungsten Carbid:

silver

Range of application:

depending on roll cover material

– Breast Rolls

– Press Rollls

– Steel Calanders

Material No.:

PW 110

Alloy No.:

2.1020 (bronze)

Description:

Cu Sn 6

Hardness:

HB: 200 – 230

Description:

acid resistant and cold rolled

Tensile strength:

650 – 740 N/mm²

Surface:

bronze cold rolled

Substrate:

bronze

Lay:

Tungsten Carbid

Hardness Tungsten Carbid:

approx. 1200 HV

Colour Tungsten Carbid

silver

Range of application:

depending on roll cover material

– Dryers

– Reel Drum

– Steel Calanders

Material No.:

PW 130

Alloy No.:

1.4310 (AISI 301)

Description:

X10CrNi18-8

Hardness:

HRC: 46 – 49

HV: 460 – 500

Description:

cold rolled stainless steel (18% chrome)

Tensile strength:

1500 – 1700 N/mm²

Surface:

bright

Susbstrate:

stainless steel

Lay:

Tungsten Carbid

Hardness Tungsten Carbid:

approx. 1200 HV

Colour Tungsten Carbid

silver

Range of application:

depending on roll cover material

– Hard Rubber

Material No.:

PW 140

Alloy No.:

1.4021 (AISI 420)

Description:

X20Cr13

Hardness:

HRC: 47 – 50

HV: 470 – 520

Description:

hardened and tempered stainless steel (13% chrome)

Tensile strength:

1500 – 1700 N/mm²

Surface:

bright polished

Susbstrate:

stainless steel

Lay:

Tungsten Carbid

Hardness Tungsten Carbid:

approx. 1200 HV

Colour Tungsten Carbid:

silver

Range of application:

depending on roll cover material

– Dryers

– Press Rolls

Material No.:

PW 150

Alloy No.:

1.0605 (AISI 1075)

Description:

C 75 S

Hardness:

HRC: 46 – 49

HV: 460 – 500

Description:

hardened and tempered carbon steel with 0.75% C

Tensile strength:

1500 – 1700 N/mm²

Surface:

bright polished

Substrate:

Carbon Steel

Lay:

Tungsten Carbid

Hardness Tungsten Carbid:

approx. 1200 HV

Colour Tungsten Carbid:

silver

Range of application:

depending on roll cover material

– Dryers

– Steel Calanders

– MG Cylinders

– Yankee Creping

Material No.:

PW 160

Alloy No.:

1.1274 (AISI 1095)

Description:

C 100 S

Hardness:

HRC: 50 – 54

HV: 530 – 600

Description:

hardened and tempered carbon steel with 1.0% C

Tensile strength:

1800 – 2000 N/mm²

Surface:

bright polished

Substrate:

Carbon Steel

Lay:

Tungsten Carbid

Hardness Tungsten Carbid:

approx. 1200 HV

Colour Tungsten Carbid:

silver

Range of application:

depending on roll cover material

– Yankee Creping

– Dryers

– MG Cylinders

Advantages of doctor blades with Tungsten Carbid:

- lower friction coefficient

- high wear resistance

- high temperature resistance

Please note the following packaging references.

![]()

Our datasheet: Doctor Blades with Tungsten Carbid

(09/2015)